Substrate Cleaning and Preparation: The first and most critical step in achieving strong adhesion with a PVD Coating Machine is meticulous substrate...

READ MORENingbo Danko Vacuum Technology Co., Ltd. Since 2020

As China Thermal evaporation & magnetron sputtering coating machine Manufacturers and Thermal evaporation & magnetron sputtering coating machine Suppliers, Danko Vacuum Technology Co., Ltd is committed to expanding our market boundaries by providing high-quality, high-performance vacuum coating equipment. Our Company is highly focused on after-sales service in Domestic and International markets, providing accurate part processing plans and professional solutions to meet customers' needs.

-

How does a PVD Coating Machine ensure adhesion strength between the substrate and the coating layer?

-

Metals as Substrates: Metals are the most common and compatible substrates for PVD Coating Machine due to their high thermal conductivity, structura...

READ MORE -

Vacuum EnvironmentThe vacuum coating machine operates in a low-pressure environment, which is one of its most critical features in ensuring the remo...

READ MORE -

1. Effect on Coating Adhesion The choice of target material plays a critical role in the adhesion of the deposited coating to the substrate. Adhesion ...

READ MORE

Provide specific application examples of thermal evaporation magnetron sputtering coating machines

Here are some specific application examples for thermal evaporation and magnetron sputtering coating machines provided by Ningbo Danko Vacuum Technology Co., Ltd.:

Thermal Evaporation Coating Applications:Optical Coatings: Thermal evaporation is widely used for depositing anti-reflective and reflective coatings on optical components like lenses, glasses, and mirrors. These coatings enhance optical performance by reducing glare and improving light transmission.

Thin Film Electronics: This method is utilized in the production of thin film transistors and sensors, particularly in displays and photovoltaic cells, where precise control over layer thickness is critical.Decorative Coatings: Thermal evaporation is effective for applying decorative metallic finishes on consumer goods, jewelry, and automotive parts, providing a visually appealing appearance while adding a layer of protection.

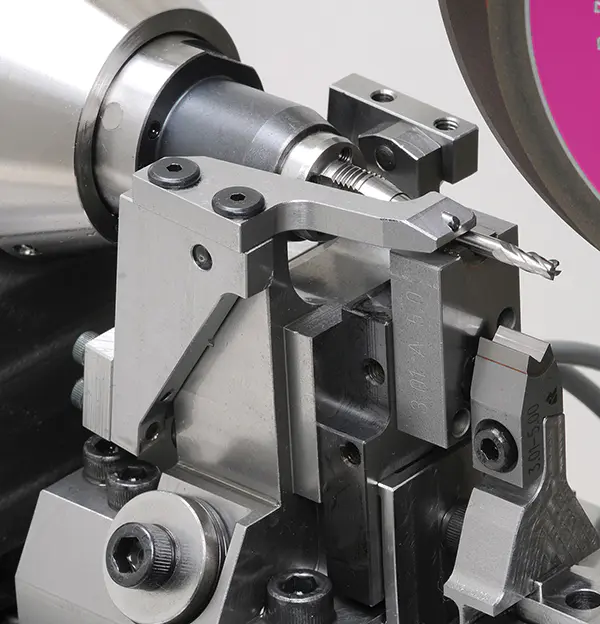

Barrier Films: Used in packaging applications, thermal evaporation creates thin barrier coatings that protect products from moisture and oxygen, extending shelf life and maintaining quality.Magnetron Sputtering Coating Applications:Hard Coatings for Tools: Magnetron sputtering is commonly used to deposit hard coatings, such as TiN (Titanium Nitride) and CrN (Chromium Nitride), on cutting tools and industrial machinery. These coatings enhance wear resistance and extend tool life.

Semiconductor Manufacturing: In semiconductor fabrication, magnetron sputtering is used for depositing thin films of metals and dielectrics, critical for integrated circuits and microelectronics.Solar Cells: This method is applied in the production of thin film solar cells, where sputtered layers of materials like cadmium telluride (CdTe) or copper indium gallium selenide (CIGS) are crucial for energy conversion efficiency.

Decorative and Functional Coatings: Magnetron sputtering is also used for applying decorative and functional coatings on automotive parts, architectural components, and consumer electronics, combining aesthetics with durability.Optical Coatings: Similar to thermal evaporation, magnetron sputtering can produce high-performance optical coatings for lenses, filters, and mirrors, offering superior uniformity and adhesion.

These application examples illustrate the versatility and effectiveness of both thermal evaporation and magnetron sputtering coating technologies across various industries, including optics, electronics, automotive, and manufacturing.

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China