1. Effect on Coating Adhesion The choice of target material plays a critical role in the adhesion of the deposited coating to the substrate. Adhesion ...

READ MORENingbo Danko Vacuum Technology Co., Ltd. Since 2020

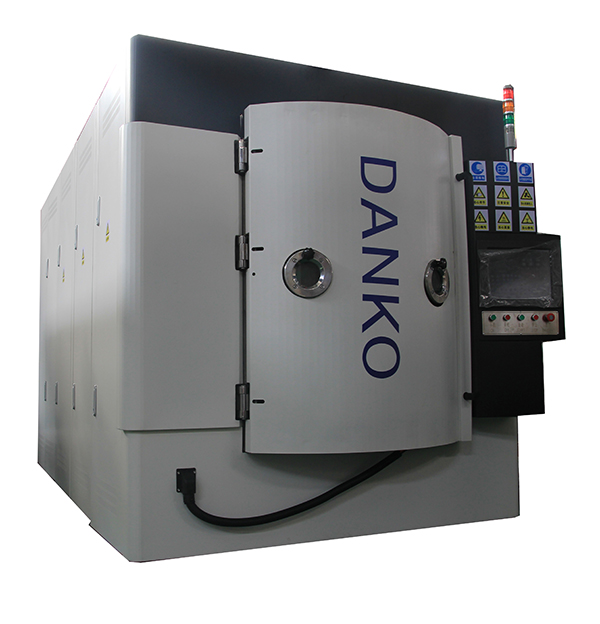

As China Magnetron Sputtering Vacuum Coating Machine Manufacturers and Magnetron sputtering coating machine Suppliers, Danko Vacuum Technology Co., Ltd is committed to expanding our market boundaries by providing high-quality, high-performance vacuum coating equipment. Our Company is highly focused on after-sales service in Domestic and International markets, providing accurate part processing plans and professional solutions to meet customers' needs.

-

-

Advanced Motion Control and Multi-Axis Positioning A high-performance Moulds coating machine relies heavily on advanced motion control systems and mul...

READ MORE -

Cathode Design and Target Erosion ManagementThe Multi-arc Ion Coating Machine relies on multiple cathode targets to generate high-energy electric arcs...

READ MORE -

Vacuum and Pressure SafetyDecorative Vacuum Coating Machines operate under high or ultra-high vacuum conditions, often ranging from millitorr to mic...

READ MORE

Precautions for daily maintenance of magnetron sputtering coating machine

Daily maintenance of magnetron sputtering coating machines is crucial for ensuring optimal performance, extending equipment lifespan, and maintaining coating quality. Here are some key precautions and practices for daily maintenance:

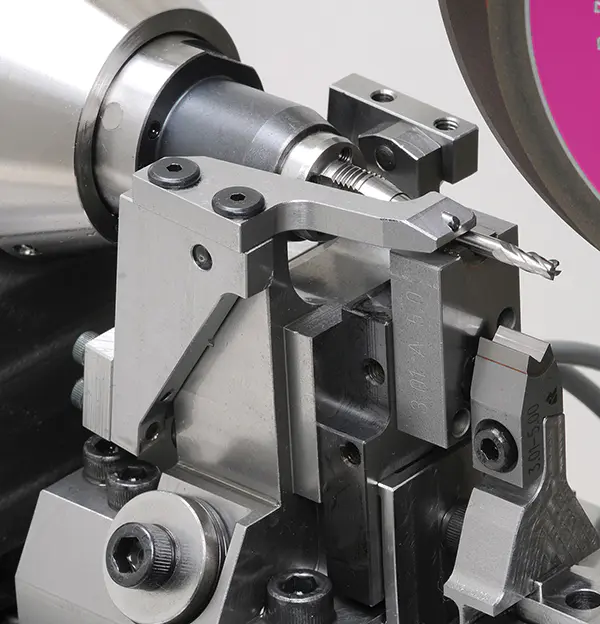

Clean the Chamber: Regularly clean the interior of the sputtering chamber to remove any residual material or contaminants. Use appropriate cleaning agents and tools to avoid scratching or damaging surfaces.Inspect Components: Check critical components such as target materials, substrates, and sputtering nozzles for wear or damage. Replace any worn parts to prevent equipment failure and ensure consistent coating quality.

Monitor Vacuum Levels: Regularly check the vacuum system to ensure it maintains the correct pressure. Any deviations could indicate leaks or problems with the pump that need to be addressed.Check Electrical Connections: Inspect all electrical connections for signs of wear, corrosion, or damage. Ensure all wiring is secure and functioning properly to prevent electrical issues during operation.

Examine Cooling Systems: If the machine has cooling systems, ensure they are functioning correctly. Check coolant levels and look for leaks or blockages that could affect performance.Clean Filtration Systems: If the system includes air or gas filtration, clean or replace filters as needed to ensure proper airflow and prevent contamination.

Lubricate Moving Parts: Apply lubricant to moving parts according to the manufacturer’s guidelines to reduce friction and wear, ensuring smooth operation.Review Control Systems: Check the control panel and software settings for any alerts or error messages. Ensure that all settings are calibrated correctly for optimal performance.

Monitor Gas Supply: Ensure that gas supplies (e.g., argon, reactive gases) are adequate and functioning correctly. Regularly check connections and gauges to prevent interruptions during operation.Document Maintenance Activities: Keep a detailed log of all maintenance activities, including inspections, repairs, and replacements. This helps in tracking the machine's performance and identifying potential issues over time.

Train Operators: Ensure that all operators are trained in proper maintenance practices and understand the importance of routine checks. Encourage them to report any unusual noises, vibrations, or performance issues immediately.Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer. Each machine may have specific needs that should be followed for optimal performance.

By following these precautions, operators can help ensure the longevity and reliability of magnetron sputtering coating machines while maintaining high-quality coating standards.

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China