Power requirements of vacuum pumps and chamber systems: In a Vacuum Coating Machine, the vacuum generation system is typically the single largest co...

READ MORENingbo Danko Vacuum Technology Co., Ltd. Since 2020

As China Power supply Manufacturers and Power supply Suppliers, Danko Vacuum Technology Co., Ltd is committed to expanding our market boundaries by providing high-quality, high-performance vacuum coating equipment. Our Company is highly focused on after-sales service in Domestic and International markets, providing accurate part processing plans and professional solutions to meet customers' needs.

-

-

How does a PVD Coating Machine ensure adhesion strength between the substrate and the coating layer?

Substrate Cleaning and Preparation: The first and most critical step in achieving strong adhesion with a PVD Coating Machine is meticulous substrate...

READ MORE -

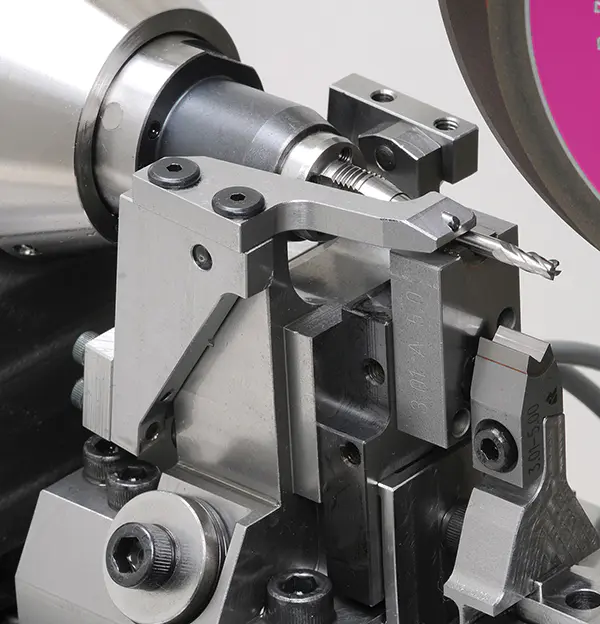

Metals as Substrates: Metals are the most common and compatible substrates for PVD Coating Machine due to their high thermal conductivity, structura...

READ MORE -

Vacuum EnvironmentThe vacuum coating machine operates in a low-pressure environment, which is one of its most critical features in ensuring the remo...

READ MORE

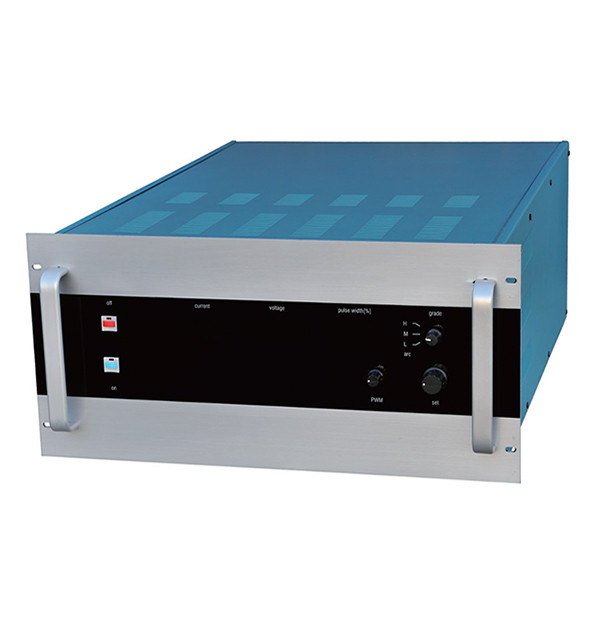

Specific installation requirements related to power supply when setting up a coating machine

When setting up a coating machine, specific installation requirements related to the power supply can include:

Voltage and Current Specifications: Ensure the power supply matches the machine’s voltage and current requirements. This includes checking the phase (single-phase or three-phase) and frequency (e.g., 50/60 Hz).Dedicated Electrical Circuit: Install a dedicated electrical circuit to prevent overload and ensure stable power delivery. This circuit should have appropriate circuit breakers and fuses.

Grounding: Proper grounding is essential to protect the equipment and operators from electrical faults. Follow local electrical codes for grounding practices.Power Quality: Assess the quality of the power supply, including voltage stability and harmonics. Power conditioning equipment may be required to mitigate issues like voltage spikes or dips.

Cable Sizing: Use appropriately sized power cables to handle the machine's current load without overheating. The cable length and installation environment can affect sizing requirements.Safety Disconnects: Install safety disconnect switches near the machine for quick access in case of emergency. These should comply with local safety regulations.

Environmental Considerations: Ensure that the installation area is suitable for electrical equipment, protecting it from moisture, dust, and extreme temperatures.Access for Maintenance: Design the layout to allow easy access to power supply components, such as circuit breakers and power panels, for maintenance and troubleshooting.

Integration with Existing Systems: If integrating into an existing facility, assess the compatibility of the new machine's power requirements with the current electrical infrastructure.Compliance with Regulations: Adhere to local and national electrical codes and regulations, ensuring that all installation practices are compliant.

Surge Protection: Implement surge protection devices to shield the machine from electrical surges that could damage sensitive components.Labeling and Documentation: Clearly label all electrical connections and document the installation for future reference and maintenance.

By addressing these installation requirements, you can ensure that the power supply setup for the coating machine is safe, reliable, and efficient, ultimately contributing to the machine's optimal performance.

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China