Operation process of Bearing Transmission Hard Vacuum Coating Machine:

Before using Bearing Transmission Hard Vacuum Coating Machine, you need to ensure that the equipment is in good working condition and check whether all parts are intact.

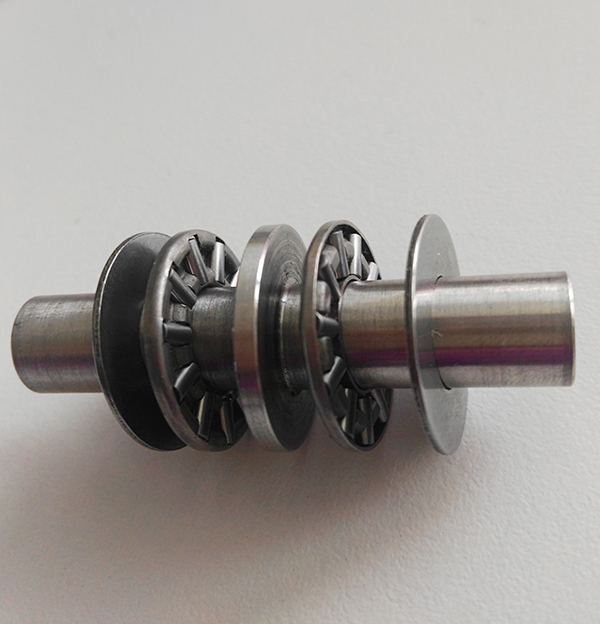

Put the cleaned bearing transmission parts into the vacuum chamber of the coating machine, and ensure that the parts are neatly placed and collision-free. Close the vacuum chamber door and start the vacuum pump to extract the air in the vacuum chamber to achieve the required vacuum degree. According to the needs, select the appropriate coating material and coating process parameters, such as coating time, temperature and air pressure. Start the coating program, and the coating machine will automatically complete the sputtering of the metal target and the coating process on the surface of the film. During this process, it is necessary to pay close attention to the operating status and coating quality of the coating machine, and adjust the parameters in time to ensure the coating effect. After the coating is completed, close the coating program, wait for the vacuum chamber to return to a safe pressure, open the vacuum chamber door, and take out the coated bearing transmission parts.

System Summary

PVD Thin Film Deposition Vacuum Coating Machine is high performing and easy operating, equipped with arc sputtering system. This machine offers a wide range of application, such as hard film coating, abrasion resistance coating and exterior coating on mechanical transmission, with DLC (diamond like coating) function to improve the hardness.

Substrates can be three-dimensional motion, to enhance the uniform of coating. The full automatic control processing is steady and perfect.

System Type

• Vertical Batch – Single or double door

Coating:

• TiN, TiC, TiCN, TiAlN, TiAlCN, TiCrN, TiCrN, TiCrCN, TiAlCrN and other multilayer super hard coatings.

APPLICATION:

• Gear transmission

• Automatic transmission

• All-wheel transmission

• Mechanical industry

• Bearing transmission

• Screw compressor

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email:

Email:  Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China