Technology

- DK Arc Ion coating

- DK DLC hard coating

- DK Optical thin film coating

- DK PVD coating

- DK Sputtering coating

- UV coating production process

- What are the advantages of PVD coating over traditional electroplating?

- What are the characteristics of PVD coating?

- What are the colors of the PVD coating?

- What are the film types of PVD coatings?

Application Categories

- DK Arc Ion coating

- DK DLC hard coating

- DK Optical thin film coating

- DK PVD coating

- DK Sputtering coating

- UV coating production process

- What are the advantages of PVD coating over traditional electroplating?

- What are the characteristics of PVD coating?

- What are the colors of the PVD coating?

- What are the film types of PVD coatings?

- What is the thickness of PVD coating?

- What substrate can PVD arc ion coat on?

Recent news

-

How does the Medical Instrument Coating Machine handle coatings for instruments that require multiple layers or different coating types?

Dec 09,2025 -

How does the Multi-arc Ion Coating Machine address contamination control within the vacuum chamber to prevent defects?

Dec 02,2025 -

How does the Multi-arc Ion Coating Machine handle high-throughput production and maintain coating quality under rapid processing conditions?

Nov 24,2025

DK DLC hard coating

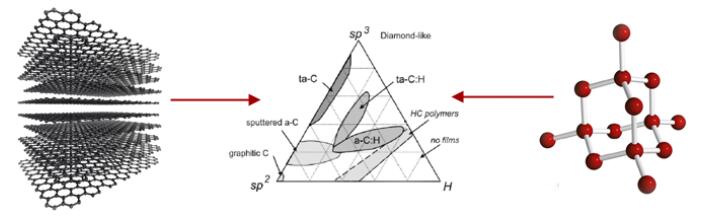

DLC-Diamond like carbon coating

Diamond-like-Carbon coatings are high performing and easy operating, equipped with arc sputtering system, which are used in demanding automotive, non-ferrous material machining and industrial engineering environments where component surfaces are subjected to high contact pressure, intermittent lubrication or dry sliding and rolling environments where severe abrasive and adhesive wear conditions exist. DLC coatings are also commonly applied onto various medical and dental instruments and implants to provide a dark black, anti-reflective and bio-compatible surface with enhanced tribological protection properties.

Coating description

The amorphous CAVIDUR coatings are especially suited for racing and other high-performance engine applications. It is deposited by a combination of PVD and PACVD processes. To guarantee good quality and performance, we perform all CAVIDUR coatings in a clean environment. The coating temperature range is 180 - 350℃. Plasma Assisted Chemical Vapor Deposition (PACVD) Is well-established for DLC layer deposition. The process activates chemical reactions through plasma excitation and ionization. We frequently apply the amorphous DYLYN coatings to parts and components for the engineering, automotive, plastics processing, and semiconductor industries. To guarantee good quality and performance, we perform DYLYN coatings in a clean environment. The coating temperature range is 180 - 220 ℃

Take the pole position

We can provide a range of different CAVIDUR coatings to match the differing requirements for various components in a racing engine’s powertrain. To help you evaluate the benefits, we can conduct a trial by applying CAVIDUR coatings to your existing parts.

Well established in the racing industry

For the past twenty years, professional motorsport teams in F1, NASCAR, WRC, DTM and F3 have trusted our CAVIDUR coatings to deliver the performance they require. Motorcycle components can also benefit from the advantages of this treatment.

Advantages

Performance boost

Reduces friction

Reduces wear and extends part life

Increases part reliability

Protects both coated component and uncoated counterpart

Low surface energy

Low micro porosity

High hardness

Low friction

Biocompatible

Excellent adhesion

Typical applications

Piston rings

Valve train components

Oil pump shafts

Components for the automotive, engineering, and semiconductor industries

Moving and form-giving mold components

Caps and closures

Ejector pins and bushings

Blow mold and forms for PET cores and bottles

Hydraulic components

Pneumatic components

Engine components

Medical and pharmaceutical industry parts Gears

Quick Link

Detailed information

Tel: +86-13486478562

Tel: +86-13486478562 FAX: +86-574-62496601

FAX: +86-574-62496601 Email: [email protected]

Email: [email protected] Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

Address: No. 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China

OEM/ODM PVD Coater Manufacturers

OEM/ODM PVD Coater Manufacturers

Email:

Email:  Tel:+86-13486478562

Tel:+86-13486478562

Language

Language  Español

Español Português

Português